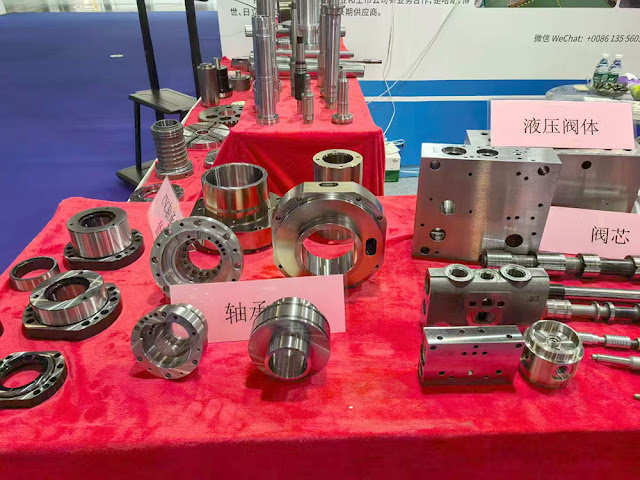

Precision Machining Manufacturing: Core Advantages and Application Industry Analysis

Precision Machining Manufacturing is a production method that uses high-precision equipment and technology to achieve micron-level processing of parts. It occupies an important position in modern industry, especially in the field of pursuing high reliability and complex design. The following is an analysis from the perspective of technical characteristics, core advantages and application industries.

1. Characteristics and advantages of Precision Machining Manufacturing

High precision and complex process

The core of Precision Machining Manufacturing is to achieve ultra-precision processing with a tolerance range of less than ±0.001 inches through technologies such as CNC machine tools and electrical discharge machining (EDM). This process can handle complex geometric shapes (such as curved surfaces and micro holes) to meet the zero-defect requirements of aerospace or medical equipment.

Technical equipment support

Combined with CAD/CAM software and automation systems, precision machining and manufacturing can quickly transform designs into entities, reduce human errors and improve efficiency. For example, a five-axis linkage CNC machine tool can complete multi-angle cutting at one time, shortening the production cycle.

Material diversity

From titanium alloys, stainless steel to engineering plastics, Precision Machining Manufacturing can adapt to the processing needs of different materials and ensure the fine processing of hard or corrosion-resistant materials.

Efficiency and cost optimization

Through modular design and mass production, companies can reduce unit costs and reduce scrap rates. For example, the medical device industry achieves small-batch customized production through precision machining to avoid inventory waste.

2. Industries that require Precision Machining Manufacturing

Aerospace

Aircraft engine blades and spacecraft precision parts need to withstand extreme environments, and have strict requirements on material strength and machining accuracy. Precision machining and manufacturing can ensure the stability of parts under high pressure and high temperature.

Medical equipment

Surgical instruments and implants (such as artificial joints) must meet biocompatibility standards and have smooth surfaces without burrs. Precision machining can achieve micron-level polishing and sterilization to ensure patient safety.

Automobile manufacturing

The motor components of new energy vehicles and the high-pressure fuel injectors of fuel vehicles rely on precision machining technology to improve energy efficiency and reduce emissions. For example, the sealing structure of Tesla battery components needs to be precisely assembled.

Electronics and Semiconductors

The manufacturing of chip packaging molds, micro sensors and other components relies on ultra-precision machining, and tolerance control directly affects product performance.

Energy Industry

The core parts of large equipment such as wind turbine gears and nuclear power plant valves need to take into account high precision and durability, and precision machining can extend their service life.

Precision Machining Manufacturing has become the cornerstone of high-end manufacturing through technological innovation and process upgrades. From microelectronic components to large energy equipment, its application scenarios continue to expand. If companies want to improve their competitiveness, they need to choose suitable precision machining solutions based on their own needs.

More recommended reading about Precision Machining Manufacturing:

1.Heat treatment and surface treatment technology in precision machining manufacturing

2.6 Common Uses and Processing Techniques for Machining Shafts

3.The impact and main advantages of precision parts processing on these 6 industries

评论

发表评论